the application of the welded wire mesh panel on the surface of the component is one of the application methods of the anti-cracking mesh. Crack prevention net is generally divided into two kinds of crack prevention net for the surface of the component and crack prevention net for the bottom of the component.

Crack mesh surface member commonly used in piers and tunnel lining surface crack, pool interior and floor surface crack, rooftop surface of the rigid waterproof layer, basement sidewall crack, floor to beam brick mold surface crack, Foundation broken surface concrete surface layer network, rock slope spray anchor concrete surface layer network and so on.

Crack network arrangement can be arranged with reference to the general method of the aforementioned conventional welded mesh will be. According to the characteristics of the use of the anti-crack network, crack network should be along the surface of the member and as close to the surface of the member (to meet the requirements of reinforced protective layer) layout. Crack layer thickness smaller mesh should be used in the form of the flat lap.

Trump folded surface formed at the intersection of the surface of the member that, on both sides of the fold line near the welded mesh should be arranged along the entire sheet folded surface. When the surface of the arc-shaped member, such as Piers, arc-shaped surface of the tunnel lining, due to the larger radius of curvature of the surface and smaller diameter steel, crack network can be installed directly bent into the desired shape.

For the floor (factory floor) surface cracking wear and other uses of welded wire mesh panel, because the wear layer thickness is small, welded steel mesh smaller diameter, welded mesh arranged in the floor surface, and should be left 20mm protective layer, welded mesh lap usually flat ride. If the split-joint requirements, the construction can be split or after the construction of sawing, seam welding network disconnection. Position by the crack, floor space layout requirements determines, and still need to consider the impact of the column position and spacing, generally taken as 6m.

Related Products:

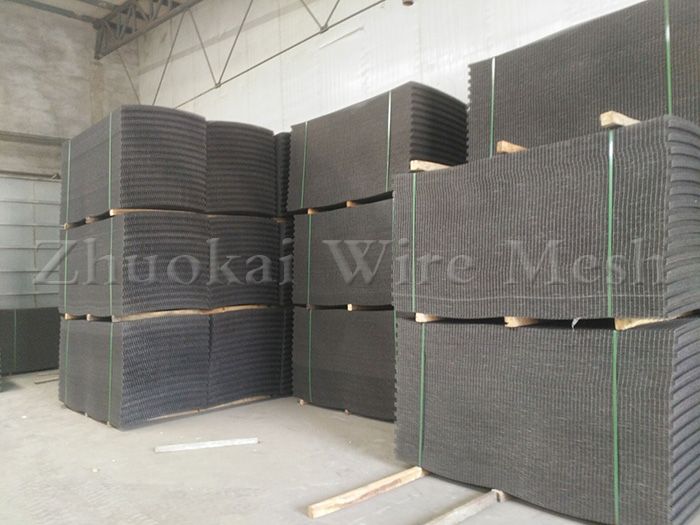

Welded Wire Mesh Panels

Temporary fence panels for sale

Livestock panel

PVC coated temporary fence panels

Hot dipped galvanized temporary fence